Premier Aluminum Llc Can Be Fun For Everyone

Premier Aluminum Llc Can Be Fun For Everyone

Blog Article

The Buzz on Premier Aluminum Llc

Table of ContentsIndicators on Premier Aluminum Llc You Need To KnowSome Known Details About Premier Aluminum Llc Premier Aluminum Llc for DummiesAn Unbiased View of Premier Aluminum Llc

(https://share.evernote.com/note/c347bf0b-f141-6fd8-d335-2be93ad98d74)Generally, a purchaser's primary duty was to find certified and responsive suppliers. In some situations, purchasers assumed that any type of distributor going to contractually meet the purchase demand was qualified. Utilizing reduced price and unqualified vendors can create high quality problems, and threw away time and money in the long run. To help you via the procedure, below are some points to think about when selecting the right metal spreading vendor.

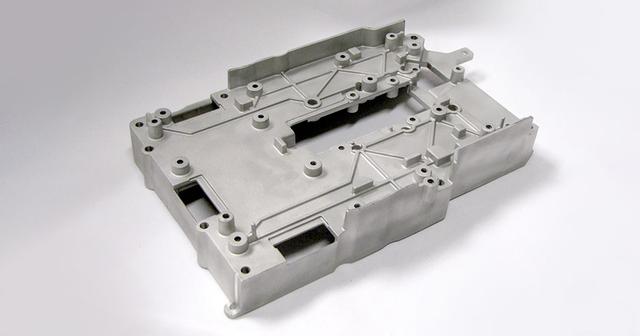

A firm that just uses the investment spreading process will try to sell you on why that process is best for your application (Aluminum Metal casting). What if using the sand casting process is best for you and your needs? Rather, look for a supplier that uses a series of casting procedures so the very best alternative for YOU is chosen

If collaborating with a solitary resource for all of your casting needs is very important to you, the vendor needs to be diverse in its abilities. When combined with other integrated abilities, this can help simplify and compress the supply base. When choosing the best casting supplier, mindful factor to consider ought to be provided to quality, service, and price.

The 15-Second Trick For Premier Aluminum Llc

Buyers increasingly pick spreading providers who have machining abilities. This can stay clear of conflict if defects are uncovered throughout machining. If a third party is machining, it might cause "finger-pointing" regarding who is at fault. Is it a casting concern or a machining problem? If the casting provider finds an issue throughout machining, the problem is solved much faster with no dispute over whose mistake it is.

What do you require from your spreading provider? Are you looking for somebody to just supply a metal part to your doorstep or do you need a lot more?

Others will certainly surpass the letter of the PO to aid you conserve time and cash. Do you have requirements for both ferrous and non-ferrous alloys? Some foundries are limited or specialized. Ensure the vendor can satisfy all your material or alloy demands to get rid of the need for multiple suppliers.

Our Premier Aluminum Llc PDFs

Research study the supplier's internet site. Talk to a sales associate or service partner.

Light weight aluminum is likewise lightweight and has good deterioration resistance, making it excellent for applications where weight and longevity are very important factors. Additionally, aluminum spreading check this is a cost-effective method of manufacturing, as it requires less energy and sources than other methods. Iron casting, on the various other hand, entails pouring molten iron right into a mold and mildew to create a wanted form.

Premier Aluminum Llc Can Be Fun For Anyone

Iron spreading is likewise able to withstand high temperature levels, making it ideal for use in applications such as engine parts and industrial equipment. Iron spreading can be a lot more pricey than aluminum casting due to the higher cost of raw materials and the energy required to melt the iron. When making a decision between aluminum spreading and iron casting, it is very important to think about the specific demands of the application.

In conclusion, both aluminum spreading and iron spreading have their very own special benefits and disadvantages. There are 3 sub-processes that drop under the classification of die spreading: gravity pass away spreading (or permanent mold casting), low-pressure die spreading and high-pressure die casting. To get to the finished product, there are 3 main alloys utilized as die spreading product to select from: zinc, light weight aluminum and magnesium. Report this page